17 Year Mine Life to Average 150,000 Gold Ounces of Production During Initial Five Years and Produce Nearly Two Million Ounces of Gold

TORONTO, Nov. 8, 2017 /CNW/ - Argonaut Gold Inc. (TSX: AR) (the "Company", "Argonaut Gold" or "Argonaut") is pleased to announce the results of a feasibility study ("FS") for its 100% owned Magino gold project ("Magino" or the "Project") located 40 kilometres northeast of Wawa, Ontario, Canada. A 10,000 tonne per day processing facility was selected for the FS in order to significantly reduce the initial capital requirement. This differs from the 30,000 tonne per day project presented in the January 2016 pre-feasibility study ("PFS") and provides the Company with a scalable project, which it can fund on a stand-alone basis, if a decision is made to proceed with the Project. The Project is designed to allow future expansion should economics warrant such a decision. A 30,000 tonne per day scenario was also evaluated, is summarized in this press release and will be described in summary in the Other Relevant Data section of the National Instrument ("NI") 43-101 Technical Report scheduled for filing within 45 days. All dollar amounts are expressed in United States dollars, unless otherwise specified (C$ refers to Canadian dollars).

Pete Dougherty, President & CEO stated: "We believe this FS demonstrates that Magino is a strategic, long-life asset in an attractive mining jurisdiction, Ontario. We have been able to appropriately scale the Project to a manageable capital number while providing the optionality of expanding the scale of the project in the future either through operational cash flow during Magino's life or through a potential joint-venture partnership. The 10,000 tonne per day project reports an average grade of 1.4 g/t Au during the first five years and 1.2 g/t Au during the 14 years of active mining. With a strong cash position, zero debt and the expectation of solid cash flow from our Mexican operations as we execute on our 60% production growth plan between 2017 and 2019, we feel that the $321 million initial capital estimate is a manageable investment for the Company, at the right time, given our ability to add debt capacity at either the corporate or project level and the cash flow anticipated from our Mexican operations. We have also been mindful when developing mine plans and designing the process facility not to sterilize the ore body and ensure proper space is available should economics warrant an investment to expand the Project to 30,000 tonnes per day in the future. Given our internal growth profile, we are focused in the near term on that growth. Decisions on Magino will be made when and if it is appropriate. The size, location, economics and expandability of Magino give Argonaut significant flexibility to explore options around the Project on its own or with partners."

The FS assumed $1,250 gold and a 0.78:1 United States dollar to Canadian dollar exchange rate. The FS yields average annual production of approximately 116,000 gold ounces over a 17 year mine life (including three years of ore processed from a low grade stockpile), an average of 150,000 gold ounces during the first five years and an average of 123,000 gold ounces during the 14 years of active mining. Estimated cash costs and all-in sustaining costs ("AISC") are $669/oz and $711/oz respectively (see Non-IFRS Measures section). The economic results of the FS are presented in Table 1 below:

Table 1: Magino Feasibility Study Economic Results

|

Parameter |

Unit |

|

|

Au Price |

US $/oz |

1,250 |

|

Exchange Rate |

US:CDN |

0.78 |

|

Production | ||

|

Mine Life (from start of commercial production) |

Yrs |

17 |

|

Au Payable |

LOM k oz |

1,964 |

|

Avg k oz/yr |

115.7 | |

|

Life-of-mine ("LOM") Net Sales Revenue (after royalties) |

US$M |

2,443 |

|

Operating Costs |

LOM US$M |

1,313 |

|

US$/t milled |

22.27 | |

|

Capital Costs | ||

|

Pre-Production |

US$M |

293 |

|

Sustaining & Closure |

US$M |

84 |

|

Subtotal |

US$M |

377 |

|

Contingency |

US$M |

28 |

|

Total Capital Costs |

US$M |

405 |

|

Operating Cash Flow |

US$M |

1,142 |

|

Cash Cost |

US$/oz |

669 |

|

All-in Sustaining Cost |

US$/oz |

711 |

|

Economic Results | ||

|

After-Tax Free Cash Flow |

US$M |

540 |

|

Avg US$M/yr |

32 | |

|

Discount Rate |

% |

5 |

|

Pre-Tax NPV5% |

US$M |

408 |

|

Pre-Tax Internal Rate of Return (IRR) |

% |

22.6 |

|

Pre-Tax Payback |

Yrs |

3.8 |

|

After-Tax NPV5% |

US$M |

288 |

|

After-Tax IRR |

% |

19.5 |

|

After-Tax Payback |

Yrs |

3.9 |

The Company has evaluated the net present value at a 5% discount rate (NPV5%) of the Project at various sensitivities, including gold price and foreign exchange rate. Table 2 below illustrates the FS after-tax NPV5% sensitivity to various gold price and foreign exchange rate assumptions:

Table 2: Magino Base Case After-Tax NPV at 5% Discount Sensitivity to Gold Price & Exchange Rate ($M)

|

Exchange |

| ||||||

|

$1,100 |

$1,150 |

$1,200 |

$1,250 |

$1,300 |

$1,350 |

$1,400 | |

|

0.72 |

$183 |

$228 |

$273 |

$317 |

$362 |

$406 |

$451 |

|

0.74 |

$173 |

$218 |

$263 |

$307 |

$352 |

$397 |

$441 |

|

0.76 |

$163 |

$208 |

$253 |

$298 |

$342 |

$387 |

$432 |

|

0.78 |

$153 |

$198 |

$244 |

$288 |

$333 |

$378 |

$422 |

|

0.80 |

$143 |

$188 |

$234 |

$279 |

$323 |

$368 |

$413 |

|

0.82 |

$132 |

$178 |

$224 |

$269 |

$313 |

$358 |

$403 |

|

0.84 |

$122 |

$169 |

$214 |

$259 |

$304 |

$348 |

$393 |

Mineral Resource Estimate

A conceptual pit was generated in order to constrain the tabulation of Mineral Resources. A gold price of $1,300 was used along with other cost, recovery and slope parameters. Mineral Resources were estimated in the conceptual pit using a 0.25 g/t gold cut-off grade. Table 3 tabulates undiluted Measured and Indicated Mineral Resources and Inferred Mineral Resources at a 0.25 g/t gold cut-off grade.

Table 3: Mineral Resource Estimate

|

Resource Category |

Tonnes |

Au |

Contained Au Ounces |

|

Measured |

37.4 |

0.84 |

1,010 |

|

Indicated |

106.6 |

0.93 |

3,187 |

|

Measured & Indicated |

144.0 |

0.91 |

4,197 |

|

Inferred |

33.2 |

0.83 |

886 |

|

Note: |

Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. It is reasonably expected that the majority of the Inferred Mineral Resources could be upgraded to Indicated Mineral Resources with continued exploration. The Mineral Resources tabulated in Table 3 are inclusive of Mineral Reserves. |

|

Numbers may not total due to rounding. |

Mineral Reserve Estimate

The Mineral Reserve estimate for the Magino open pit was constrained with estimates of gold price, mining dilution, process recovery, operating costs, pit slope angles, and refining/transport costs.

The Mineral Resource block model for the Magino deposit was then used to determine optimal mining shells and pit phasing. Measured and Indicated Mineral Resources were included in the pit optimization process. Inferred Mineral Resources within the designed open pit are treated as waste.

Detailed pit and phase designs were created based on the pit optimization results. These designs incorporated geotechnical parameters as well as ramp accesses and formed the basis of the Mineral Reserve estimate.

A gold cut-off grade of 0.41 g/t was used to calculate the Mineral Reserve estimate for Magino. The FS Mineral Reserve estimate is summarized in the Table 4:

Table 4: Mineral Reserve Estimate

|

Reserve Class |

Diluted Tonnage (Mt) |

Diluted Grade |

Contained Gold |

|

Proven |

24.2 |

1.03 |

804 |

|

Probable |

34.7 |

1.19 |

1,332 |

|

Total Proven & Probable |

59.0 |

1.13 |

2,137 |

|

Notes: |

Mineral Reserves are based on the mine production schedule. |

|

Mineral Reserves include 3% ore loss and 20% dilution. | |

|

Cut-off grade varies by year as per the production schedule (marginal cut-off is 0.41 g/t Au). | |

|

A gold price of US$1,200/ounce and an exchange rate of US$0.78 to C$1.00 have been assumed. | |

|

Numbers may not total due to rounding. |

Mineral Processing, Metallurgical Testing and Recovery Methods

The metallurgical testing was completed at McClelland Laboratories Inc. Recent work focused on optimizing processing conditions and a further evaluation of ore variability within the Magino deposit. The testing program included gravity concentration and leach optimization testing.

Results from the program suggest an optimum grind size of P80 75 microns, demonstrated gold recoveries ranging from 90 to 94% from an average head grade sample of 1.31 g/t Au. The work confirmed the basic flowsheet previously adopted in the January 2016 PFS but resulted in some optimization design criteria detail such as leach retention time and reagent consumption data.

Flowsheet development and design criteria were based on metallurgical test work results. The process plant was designed on a throughput of 10,000 tonnes of ore per day with an average gold head grade of 1.25 g/t and to achieve an overall 92.0% gold recovery. The adopted flowsheet includes primary crushing, single stage semi-autogenous grinding, a gravity recovery circuit, cyanide leach and carbon-in-pulp gold adsorption circuit with cyanide recovery and detoxification and thickening prior to tailings discharge to a tailings facility. Table 5 summarizes the process criteria selected for process design and Project economics:

Table 5: Process Design Criteria Summary

|

Criteria |

Unit |

Value |

|

Overall Plant Feed |

t/d |

10,000 |

|

Crushing Circuit Throughput Rate |

t/h |

556 |

|

Grinding and Leach Process Rate |

t/h |

453 |

|

Grinding Circuit Product Size, 80% Passing |

µm |

75 |

|

Leach Circuit Retention Time |

h |

36 |

|

Cyanide Concentration, Leach Feed |

ppm |

750 |

|

Cyanide Consumption1 |

kg NaCN/t |

0.2 for shallow, mid & deep ores 0.4 for deep-deep ores |

|

Lime Requirement, CaO |

kg/t |

0.8 for shallow, mid & deep ores 0.7 for deep-deep ores |

|

Detoxification Method |

SO2/Air | |

|

Detoxification Limit (Discharge to TMF) |

ppm CNWAD |

< 1.0 |

|

CIP Circuit Retention Time-Design |

h |

1.9 |

|

Elution/stripping Circuit Capacity |

t |

4 |

|

Gold Head Grade, LOM Average |

Au, g/t |

1.25 |

|

Anticipated Gold Recovery, Design |

Au, % |

92.0 |

|

Note 1: Values include recirculation of cyanide from tailings wash thickener. |

Mine Plan and Production Schedule

Open pit mining of the Magino deposit is intended to produce a total of 59.0 million tonnes (Mt) of ore and 232.4 Mt of waste for a 3.9:1 overall strip ratio, over a 15-year mine production life (including one year of pre-production). The current life of mine plan focuses on achieving consistent ore production rates, and mining of higher value material, as well as balancing grade and strip ratios. Lower grade material that is above the marginal cut-off but below the operational cut-off will be stockpiled and processed at the end of mine life (years 14 through 17). Table 6 summarizes the pit design ore tonnages and grades for the open pit deposit:

Table 6: Proposed Mining Plan

|

Description |

Unit |

Value |

|

Mine Production Life (incl. pre-prod) |

yr |

15 |

|

Process Diluted Ore Feed |

Mt |

59.0 |

|

Diluted Gold Grade (head grade) |

g/t |

1.13 |

|

Contained Gold |

koz |

2,137 |

|

Waste |

Mt |

232.4 |

|

Total material |

Mt |

291.4 |

|

Strip Ratio |

t:t |

3.9 |

Open pit mining operations will use a fleet comprised of 16 m3 front shovels, a 13 m3 front-end loader and 140 t haul trucks. This fleet will be supplemented by drills, graders, and track and rubber-tire dozers. A 5 metre working bench height was selected for mining in ore and waste with overall 10 metre effective bench height based on a double bench configuration.

Mining will begin at the Project in the year preceding full operations to provide waste rock for general construction, as well as construction of the first lift of the containment structure at the tailings facility. This will also enable the stockpiling of higher grade ore prior to the start of mill processing. Mill processing will commence in year 1. Open pit mining will be completed in the first half of year 14. Mill processing of lower grade material will continue until the first quarter of year 17. Table 7 summarizes the life of mine material movement by year for both the mine and the processing facility:

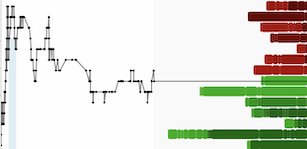

Table 7: Mine Production Schedule

|

|

|

Waste |

|

|

|

|

|

Pre- |

0.4 |

9.1 |

|

20.6 |

|

|

|

1 |

4.9 |

13.5 |

3.40 |

2.7 |

1.43 |

144 |

|

2 |

6.1 |

14.4 |

3.65 |

2.4 |

1.43 |

155 |

|

3 |

4.7 |

17.3 |

3.65 |

3.7 |

1.14 |

123 |

|

4 |

5.8 |

16.7 |

3.65 |

2.9 |

1.52 |

165 |

|

5 |

4.8 |

19.7 |

3.65 |

4.1 |

1.50 |

162 |

|

6 |

4.1 |

22.9 |

3.65 |

5.6 |

1.21 |

131 |

|

7 |

3.6 |

23.4 |

3.65 |

6.4 |

1.06 |

114 |

|

8 |

3.6 |

23.4 |

3.65 |

6.4 |

0.96 |

103 |

|

9 |

3.6 |

23.4 |

3.65 |

6.4 |

1.12 |

121 |

|

10 |

3.6 |

20.5 |

3.65 |

5.6 |

1.19 |

128 |

|

11 |

3.6 |

11.1 |

3.65 |

3.0 |

1.31 |

142 |

|

12 |

3.6 |

5.7 |

3.65 |

1.6 |

1.24 |

133 |

|

13 |

3.6 |

5.7 |

3.65 |

1.6 |

1.15 |

124 |

|

14 |

2.6 |

5.8 |

3.65 |

2.2 |

1.04 |

113 |

|

15 |

N/A |

N/A |

3.65 |

N/A |

0.45 |

49 |

|

16 |

N/A |

N/A |

3.65 |

N/A |

0.45 |

49 |

|

17 |

N/A |

N/A |

0.81 |

N/A |

0.45 |

11 |

|

Total |

59.0 |

232.4 |

59.0 |

3.9 |

1.13 |

1,966 |

Capital Costs

The capital cost estimate includes the costs required to develop, sustain, and close the operation for a planned 17-year mine life, which includes three years of processing low grade, stockpiled material. Major construction at site is expected to take place over a 24-month period. The sustaining capital is carried over operating years one through 16 and closure costs are projected over years 17 to 22. Table 8 details the high-level capital cost estimate:

Table 8: Summary of Life of Mine Capital Costs

|

Description |

Estimate |

|

Mining |

42.2 |

|

On-Site Development |

39.8 |

|

Mineral Processing |

107.8 |

|

Infrastructure |

36.0 |

|

Project Indirects |

24.1 |

|

EPCM |

30.5 |

|

Owner's Cost |

12.1 |

|

Contingency |

28.4 |

|

Total Initial Capital |

320.9 |

|

Sustaining Capital |

67.3 |

|

Closure Cost |

16.9 |

|

Total Sustaining/Closure Capital |

84.2 |

|

Total Capital Costs |

405.0 |

Operating Costs

The FS operating cost estimate includes the costs required to mine, handle and transport ore to the mill, mill and process the ore to doré, general and administrative expenses, as well as water treatment plant operating costs. The life of mine operating costs and unit costs are summarized in Table 9:

Table 9: Life of Mine Total Operating Cost and Unit Cost Estimate

|

Description |

Estimate |

Unit Cost (US$/tonne) |

Unit Cost (US$/payable oz) |

|

Mining |

652.9 |

11.07 |

332 |

|

Re-handle |

11.0 |

0.19 |

6 |

|

Equipment Lease |

44.4 |

0.75 |

23 |

|

Processing |

451.5 |

7.66 |

230 |

|

G&A |

141.5 |

2.40 |

72 |

|

Refining |

9.8 |

0.17 |

5 |

|

Royalties |

1.8 |

0.03 |

1 |

|

Total Operating Costs |

1313.01 |

22.27 |

669 |

Environmental Assessment and Permitting

The Company submitted its Environmental Impact Statement in January 2017 and the environmental permitting process is well underway. Federal and provincial regulators have completed their conformity review and held Indigenous and public sessions. Currently, the Company is responding to technical comments and continues its substantive engagement activities with the federal and provincial governments, as well as Indigenous communities, local municipalities and other community stakeholders.

The Company anticipates providing responses to technical comments during the fourth quarter of 2017, which would target final environmental assessment and closure plan approvals during 2018. This, in turn, will allow the Company to apply for and receive necessary permits to begin construction of all major infrastructure.

Formal agreements have been signed with the Missanabie Cree First Nation and the Red Sky Métis Independent Nation. The Company continues to consult with and work towards agreements with other Indigenous communities.

30,000 Tonne Per Day Opportunity

While the FS offers a strong economic result, represents the preferred option and is expected to be the best use of the available Mineral Resources considering the current market conditions and Company profile, an increased throughput option at a processing rate of 30,000 tonnes per day was also evaluated ("30ktpd Case"). The Company believes that 30,000 tonnes per day throughput provides interesting project optionality for the future on a stand-alone basis should economics support such a decision. The Company also sees a path whereby the 30ktpd Case could be fully evaluated and pursued as a preferred development scenario for the Project should Magino become part of a joint-venture agreement with a third party that provides greater value for Argonaut shareholders than the FS.

The 30ktpd Case is preliminary in nature and is based on the same Measured and Indicated Mineral Resources as stated in the FS, does not support Mineral Reserve estimation and should not be considered an update or replacement for the FS. The 30ktpd Case is only intended to show the potential of an increased throughput should market conditions change or an alternative commercial structure that potentially provides greater value to Argonaut shareholders than the FS is successfully negotiated.

Mine Plan Comparison

The 30ktpd Case used a lower cut-off grade than the FS to account for the decreased unit operating costs associated with higher production rates. In general, the marginal cut-off grade used was 0.34 g/t Au. Only Measured and Indicated Mineral Resources from the FS were used in the 30ktpd Case conceptual mine plan. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability.

The total mineralized material that is above the marginal cut-off grade in the 30ktpd Case is approximately double that in the FS. However, due to higher plant throughput, the grade is approximately 0.2 g/t lower and the mine life is approximately six years shorter. Contained gold is increased by approximately 1.1 million ounces. The conceptual tonnes, grade and ounces of the 30ktpd Case compared to the FS is summarized in Table 10:

Table 10: Mine Plan Comparison

|

Description |

Unit |

30ktpd Case* |

FS |

|

Total Mineralized Material Mined |

Mt |

112 |

59 |

|

Total Waste Mined |

Mt |

423** |

232 |

|

Total Mined |

Mt |

535 |

291 |

|

Average Gold Grade |

g/t |

0.9 |

1.1 |

|

Processing Rate |

t/d |

30,000 |

10,000 |

|

Production life |

years |

11 |

17*** |

|

Total Contained Gold |

Moz |

3.2 |

2.1 |

|

Notes: |

*Conceptual estimates ONLY |

|

**Waste material for increased throughput case includes lower grade material | |

|

***Production life for FS includes 2.25 years of processing lower grade material at end of mine life |

Economic Analysis

The economic results for the 30ktpd Case utilized the same assumptions as the FS ($1,250 gold and 0.78:1 USD:CAD exchange rate). The 30ktpd Case yields average annual production of approximately 269,000 gold ounces over an 11 year mine life (including one and a half years of ore processed from a low grade stockpile) and an average of 319,000 gold ounces during the first five years. Estimated cash costs and AISC are $664/oz and $721/oz respectively (see Non-IFRS Measures section). Table 11 summarizes the economic results of the 30ktpd case:

Table 11: Summary of Economic Results from 30ktpd Case

|

Parameter |

Unit |

30ktpd Case |

|

Au Price |

US $/oz |

1,250 |

|

Exchange Rate |

US:CDN |

0.78 |

|

Production | ||

|

Mine Life (from start of commercial gold production) |

Yrs |

11 |

|

Au Payable |

LOM k oz |

2,960 |

|

Avg k oz/yr |

269.1 | |

|

LOM Net Sales Revenue (after royalties) |

US$M |

3,686 |

|

Operating Costs |

LOM US$M |

1,967 |

|

US$/t milled |

17.63 | |

|

Capital Costs | ||

|

Pre-Production |

US$M |

561 |

|

Sustaining & Closure |

US$M |

167 |

|

Subtotal |

US$M |

727 |

|

Contingency |

US$M |

49 |

|

Total Capital Costs |

US$M |

776 |

|

Operating Cash Flow |

US$M |

1,733 |

|

Cash Cost |

US$/oz |

664 |

|

All-in Sustaining Cost |

US$/oz |

721 |

|

Economic Results | ||

|

After-Tax Free Cash Flow |

US$M |

701 |

|

Avg US$M/yr |

64 | |

|

Discount Rate |

% |

5 |

|

Pre-Tax NPV5% |

US$M |

588 |

|

Pre-Tax Internal Rate of Return (IRR) |

% |

23.2 |

|

Pre-Tax Payback |

Yrs |

4.3 |

|

After-Tax NPV5% |

US$M |

399 |

|

After-Tax IRR |

% |

18.9 |

|

After-Tax Payback |

Yrs |

4.4 |

Capital and Operating Costs

Capital and operating costs for the 30ktpd Case are shown in Tables 12 and 13:

Table 12: Summary of Capital Costs – 30ktpd Case

|

Description |

Estimate |

|

Mining |

124.3 |

|

On-Site Development |

61.4 |

|

Mineral Processing |

236.7 |

|

Infrastructure |

56.9 |

|

Project Indirects |

39.1 |

|

EPCM |

31.3 |

|

Owner's Cost |

11.0 |

|

Contingency |

48.8 |

|

Total Initial Capital |

609.5 |

|

Sustaining Capital |

149.1 |

|

Closure Cost |

17.6 |

|

Total Sustaining/Closure Capital |

166.7 |

|

Total Capital Costs |

776.2 |

Table 13: Summary of Operating Costs – 30ktpd Case

|

Description |

Estimate |

Unit Cost (US$/tonne) |

Unit Cost (US$/pay oz) |

|

Mining |

951.4 |

8.52 |

321 |

|

Re-handle |

30.0 |

0.27 |

10 |

|

Equipment Lease |

135.4 |

1.21 |

46 |

|

Processing |

708.6 |

6.35 |

239 |

|

G&A |

124.6 |

1.12 |

42 |

|

Refining |

14.8 |

0.13 |

5 |

|

Royalties |

2.4 |

0.02 |

1 |

|

Total Operating Costs |

1,967.3 |

17.63 |

664 |

Bill Zisch, Chief Operating Officer, commented: "We are fortunate that the Magino deposit is an ore body that lends itself to scalability. Having the ability to right size the Project, in terms of initial capital, for our size of company and current market conditions while maintaining optionality for the future is a significant benefit to the organization. We will continue through the Environmental Assessment process and permitting and then gauge market conditions and all available options for Magino to best unlock value for our shareholders."

Contribution, Work and Qualified Persons

Table 14 details the Qualified Persons ("QP") and their respective area of responsibility in the FS.

Table 14: Qualified Persons

|

QP |

Company |

Report Section(s) of Responsibility |

|

Mr. Michael Makarenko, P. Eng. |

JDS Energy & Mining |

Introduction, Reliance on others, Description/Location, |

|

Mr. Dino Pilotto, P. Eng. |

JDS Energy & Mining |

Mining reserve estimate, Mining methods, Mining Cap-ex and Op-ex estimate |

|

Mr. Michael Lechner, P. Geo. |

Resource Modeling Inc. |

Geological setting, Mineralization, Deposit types, Exploration, Drilling, |

|

Mr. Luiz Castro, P. Eng. |

Golder Associates |

Geotechnical criteria (open pit) |

|

Ms. Sindy Cheng, P. Eng. |

Lycopodium Limited |

Mineral processing, Metallurgical test work interpretation and Process Cap-ex |

|

Dr. Ian Hutchison, PhD., PE |

SLR Consulting |

Other significant factors and risks, Infrastructure: Public by-pass road, Site |

Technical information included in this release was supervised and approved by Michael Makarenko, an independent QP under NI 43-101. For further information on the Magino project, please see the reports as listed below on the Company's website or on www.sedar.com:

|

Magino Gold Project |

Preliminary Feasibility Study Technical Report on the Magino Project, Wawa, Ontario, Canada dated February 22, 2016 (effective date January 18, 2016) |

Non-IFRS Measures

The Company has included certain non-IFRS measures including "Cash cost per gold ounce sold" and "All-in sustaining cost per gold ounce sold" in this press release, which are presented in accordance with International Financial Reporting Standards ("IFRS"). Cash cost per gold ounce sold is equal to production costs divided by gold ounces sold. All-in sustaining cost per gold ounce sold is equal to production costs plus general and administrative expenses, exploration expenses, accretion of reclamation provision and sustaining capital expenditures divided by gold ounces sold. The Company believes that these measures provide investors with an improved ability to evaluate the performance of the Company. Non-IFRS measures do not have any standardized meaning prescribed under IFRS. Therefore they may not be comparable to similar measures employed by other companies. The data is intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS. Please see the most recent management's discussion and analysis for full disclosure on non-IFRS measures.

Cautionary Note Regarding Forward-looking Statements

This press release contains certain "forward-looking statements" and "forward-looking information" under applicable Canadian securities laws concerning the business, operations and financial performance and condition of Argonaut Gold Inc. ("Argonaut" or "Argonaut Gold"). Forward-looking statements and forward-looking information include, but are not limited to, statements with respect to estimated production and mine life of the mineral projects of Argonaut; the ability to obtain permits for operations; synergies; the realization of mineral reserve estimates; the timing and amount of estimated future production; costs of production; the benefits of the development potential of the properties of Argonaut; the future price of gold, copper, and silver; the estimation of mineral reserves and resources; success of exploration activities; currency exchange rate fluctuations; and financial impact of completed acquisitions. Except for statements of historical fact relating to Argonaut, certain information contained herein constitutes forward-looking statements. Forward-looking statements are frequently characterized by words such as "plan," "expect," "project," "intend," "believe," "anticipate", "estimate" and other similar words, or statements that certain events or conditions "may", "should" or "will" occur. Forward-looking statements are based on the opinions and estimates of management at the date the statements are made, and are based on a number of assumptions and subject to a variety of risks and uncertainties and other factors that could cause actual events or results to differ materially from those projected in the forward-looking statements. Many of these assumptions are based on factors and events that are not within the control of Argonaut and there is no assurance they will prove to be correct.

Factors that could cause actual results to vary materially from results anticipated by such forward-looking statements include variations in ore grade or recovery rates, changes in market conditions, risks relating to the availability and timeliness of permitting and governmental approvals; risks relating to international operations, fluctuating metal prices and currency exchange rates, changes in project parametres, the possibility of project cost overruns or unanticipated costs and expenses, labour disputes and other risks of the mining industry, failure of plant, equipment or processes to operate as anticipated.

These factors are discussed in greater detail in Argonaut's most recent Annual Information Form and in the most recent MD&A filed on SEDAR, which also provide additional general assumptions in connection with these statements. Argonaut cautions that the foregoing list of important factors is not exhaustive. Investors and others who base themselves on forward-looking statements should carefully consider the above factors as well as the uncertainties they represent and the risk they entail. Argonaut believes that the expectations reflected in those forward-looking statements are reasonable, but no assurance can be given that these expectations will prove to be correct and such forward-looking statements included in this press release should not be unduly relied upon. These statements speak only as of the date of this press release.

Although Argonaut has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking statements, there may be other factors that cause actions, events or results not to be anticipated, estimated or intended. There can be no assurance that forward-looking statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Argonaut undertakes no obligation to update forward-looking statements if circumstances or management's estimates or opinions should change except as required by applicable securities laws. The reader is cautioned not to place undue reliance on forward-looking statements. Statements concerning mineral reserve and resource estimates may also be deemed to constitute forward-looking statements to the extent they involve estimates of the mineralization that will be encountered if the property is developed. Comparative market information is as of a date prior to the date of this document.

About Argonaut Gold

Argonaut Gold is a Canadian gold company engaged in exploration, mine development and production activities. Its primary assets are the production stage El Castillo mine and San Agustin mine, which together form the El Castillo Complex in Durango, Mexico and the production stage La Colorada mine in Sonora, Mexico. Advanced exploration stage projects include the San Antonio project in Baja California Sur, Mexico, and the Magino project in Ontario, Canada. The Company also has several exploration stage projects, all of which are located in North America.

SOURCE Argonaut Gold Ltd.

View original content with multimedia: http://www.newswire.ca/en/releases/archive/November2017/08/c5998.html