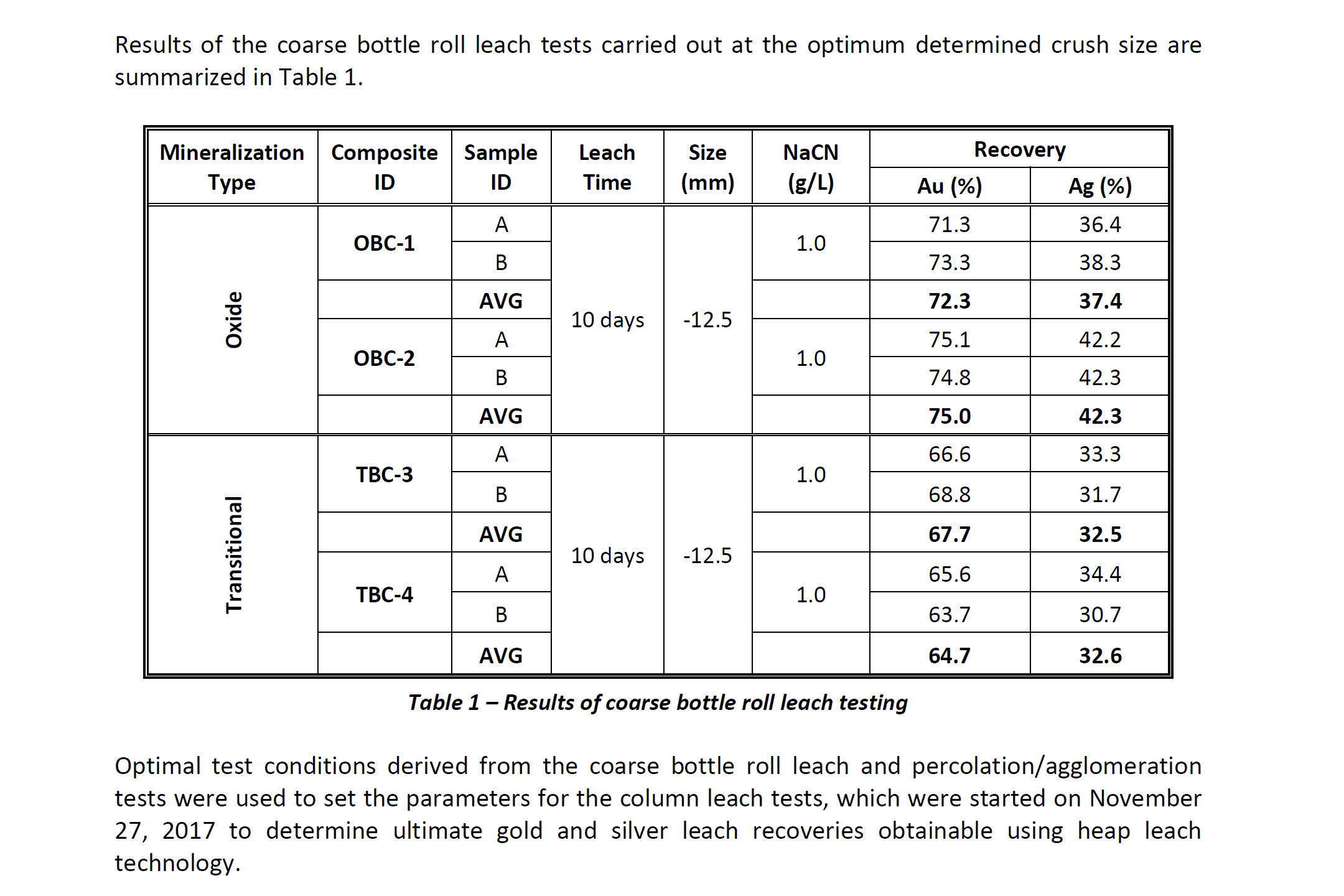

What happened? First set of results from metallurgical testing on mineralization from the “gold oxide cap” at Hamama West.

So what? Good gold and silver recoveries from a coarse crush size will reduce capital and operating costs for the heap leach project compared to a conventional CIL process.

What next? Already 10 days into the column leach testing that simulates heap leach technology, which will determine the actual expected recoveries for the Hamama West “oxide gold cap” mineralization, and will form the basis for a key part of the economic study for this gold mine in Egypt.

CEO Mark Campbell told me that the average oxide sample recovery of 73.6% was "at the upper end of expectations." which is good for this stage. Final predicted gold and silver recoveries from heap leaching will be reported once the column leach tests are completed.

Keep in mind that Aton Resources (TSXV:AAN) already reported +85% oxide gold recovery in 2015, which was achieved at a finer grind size with leach reagents; akin to using a conventional CIL circuit. There is a capital and operating cost trade-off between adopting a conventional CIL compared to heap leach technology. Adopting a lower capital and operating cost option in the form of heap leach will enable Aton to get into commercial production quicker.

It is pleasing to note that Aton are considering a heap leach option at this stage because it suggests that they are evaluating the possible process option routes and overall project economics, which will enable them to get into commercial production as soon as possible. There is the trade-off between heap leach and conventional CIL i.e. lower capex and operating costs are traded off with lower gold and silver recoveries.

Results from the coarse bottle roll leach tests are a precursor to the larger scale definitive column leach tests. Column leach tests are directly scalable to full scale heap leach operation. The encouraging aspect of the coarse bottle roll leach test results is that recoveries for the oxide and transitional ore types were similar. I've seen recoveries range from 45%-95% within one deposit and it is good to see that recoveries from the coarse bottle roll leach tests are encouraging and above average for heap leach technology. The results suggest that there is little metallurgical variability between the oxide and the transitional ore types, with higher recovery from the oxide ore zone attributable to more intense weathering.

The results reported today were completed by a reputable group that covered the full range of head assays, coarse and fine bottle roll leach tests, and percolation and agglomeration tests. They tested different combinations of crush size and cyanide concentration to determine the optimal parameters for the column leach tests, which are already 10 days in and are showing fast initial leach kinetics. It’s very important that the metallurgical testwork continues to move quickly because Aton has a tight timeline. It’s also important that Aton continues to demonstrate best practices in their activities as a junior exploration company and I believe the news release today is yet another sign that things are moving in the right direction.