BISHOP, Calif., Oct. 21, 2024 (GLOBE NEWSWIRE) -- North Bay Resources Inc. (the “Company” or “North Bay”) (OTC: NBRI) is pleased to announce the United States Department of Labor, Mining Safety and Health Administration (“MSHA”) for the Western District has issued all necessary approvals for the commencement of full-scale production at the Company’s Mt. Vernon Gold Mine located in Sierra County, California. The Company has received specific notices as follows:

- The application for Alternative Mine Rescue Capability for small and remote mines dated 10/11/2024 has been reviewed for compliance with the provisions of CFR 49.3 is approved;

- The Ventilation Plan dated 10/11/2024 has been received and reviewed for compliance with 30 CFR §57.8520---Ventilation Plan: no deficiencies noted;

- The Escape and Evacuation Plan for the Mt. Vernon Mine, Mine I.D. # 04-04088 dated 10/11/2024 as required by 30 CFR §57.11053 has been reviewed and is approved.

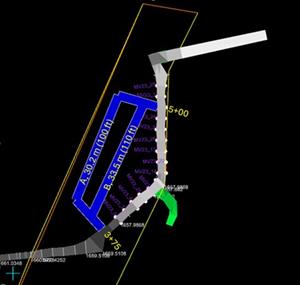

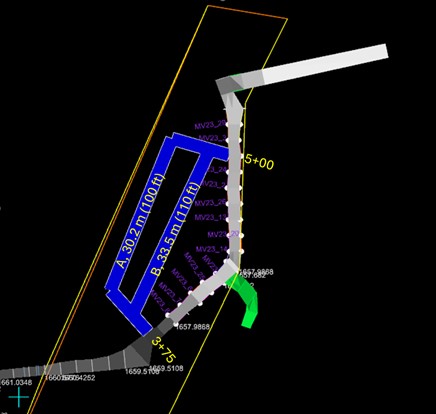

The first phase of mining will be to blast, load, sort and ship 500 tons from the heart of the deposit. This zone has shown consistent gold grades over 1 ounce and up to 5 ounces per ton gold. An updated mine plan has been completed by Respec (Mining Engineers) targeting the highest grade zone (see Diagram 1).

Diagram 1. – Updated Mine Plan for Extraction of 500 tons.

The updated mine plan utilized previous geological mapping and 3D modelling of the known high-grade channel and recent (see Press Release dated October 4, 2024) as well as previous assays (see Press Release dated July 17, 2024) as follows:

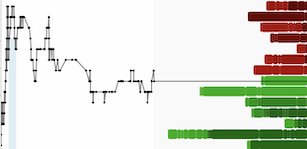

Mt. Vernon Assays - October 2024

| Sample I.D. | Location | Gold | Silver | Platinum | Palladium | Rhodium |

| oz/ton | oz/ton | oz/ton | oz/ton | oz/ton | ||

| 2021263288 | Right Cross Cut L | 3.29 | 0.37 | 1.23 | 0.02 | N.D. |

| 2021263224 | Right Cross Cut R | 3.39 | 0.36 | 0.91 | 0.47 | 0.16 |

| 2021263294 | 3+90-4+00 L | 1.17 | 0.32 | 0.66 | 0.02 | N.D. |

| 2021263225 | 4+30-4+40 L | 1.63 | 0.38 | 1.29 | 0.32 | 0.33 |

| 2021263223 | 4+40-4+50 L | 4.92 | 0.39 | 1.15 | 0.02 | N.D. |

| 2021263226 | 4+50-4+60 L | 5.02 | 0.48 | 1.49 | 0.25 | 0.45 |

| 2021263222 | 4+70-4+80 L | 4.01 | 0.48 | 1.44 | 0.14 | N.D. |

| 2021263227 | 3+90-4+00 R | 2.17 | 0.67 | 1.34 | 0.16 | N.D. |

| 2021263221 | 4+10-4+20 R | 3.71 | 0.31 | 1.03 | 0.16 | 0.21 |

| 2021263220 | 4+20-4+30 R | 3.00 | 0.67 | 1.28 | 0.42 | 0.26 |

| 2021263291 | 4+40-4+50 R | 1.28 | 0.33 | 1.15 | 0.32 | N.D. |

| 2021263289 | 5+10-5+20 R | 0.69 | 0.70 | 1.30 | 0.45 | 0.29 |

Mt. Vernon Assays – October 2023

| Sample ID | Location | Gold |

| oz/ton | ||

| MV23-8 | 3+90-4+00 L | 2.11 |

| MV23-7 | 4+00-4+10 L | 2.02 |

| MV23-6 | 4+10-4+20 L | 1.35 |

| MV23-25 | 4+20-4+30 L | 2.10 |

| MV23-18 | 4+30-4+40 L | 3.22 |

| MV23-12 | 4+40-4+50 L | 4.80 |

| MV23-14 | 4+50-4+60 L | 2.48 |

| MV23-23 | 4+60-4+70 L | 1.82 |

| MV23-13 | 4+70-4+80 L | 2.83 |

| MV23-26 | 4+80-4+90 L | 1.52 |

| MV23-2 | 4+90-5+00 L | 2.57 |

| MV23-24 | 5+00-5+10 L | 1.06 |

| MV23-9 | 5+10-5+20 L | 0.67 |

| MV23-3 | 5+20-5+30 L | 0.94 |

| MV23-29 | 5+30-5+40 L | 0.93 |

| MV23-17 | 3+90-4+00 R | 2.01 |

| MV23-10 | 4+10-4+20R | 2.4 |

| MV23-19 | 4+20-4+30 R | 2.21 |

| MV23-28 | 4+30-4+40 R | 1.32 |

| MV23-16 | 4+40-4+50 R | 1.58 |

| MV23-21 | 4+50-4+60 R | 1.27 |

| MV23-20 | 4+60-4+70 R | 1.85 |

| MV23-11 | 4+70-4+80 R | 0.74 |

| MV23-27 | 4+80-4+90 R | 1.19 |

| MV23-1 | 4+90-5+00 R | 0.85 |

| MV23-4 | 5+00-5+10 R | 1.70 |

| MV23-15 | 5+10-5+20 R | 1.21 |

| MV23-5 | 5+20-5+30 R | 0.40 |

| MV23-22 | 5+30-5+40 R | 0.38 |

Mt. Vernon Gold Mine

The Mt. Vernon Gold Mine is a largely undeveloped deposit. Sampling, by qualified mining engineers, have assayed greater than 1 ounce per ton, and up to 5 ounces per ton, continuously reported over 200 feet. The modern access tunnel runs across the known 200-foot-wide gold bearing zone and perpendicular to the channel itself. The channel is up to 500 feet wide and extends over 2000 feet in length throughout the property. The channel varies in thickness from 4 feet to up to 20 feet. Typically, the lower 4 feet contains the higher gold grades. The channel is the same channel previously mined at the contiguous Ruby Mine which is known to be the richest mine in North America. Mt. Vernon is a permitted underground mine with modern portal, tunnel, ventilation. power, and equipment. The ore body is estimated at 954,000 tons based on the known channel (B. Hanford, 2023).

Bishop Gold Mill

The gravity circuit at the Company’s Bishop Gold Mill is now operational and the processing of gold bearing ore from the Company’s Fran Gold project is expected to commence this week. Woods Process Services personnel will be on site Tuesday, October 22 to complete final electrical inspection prior to processing of gold bearing ore having already completed mechanical inspection. Operational components include jaw crusher (see Press Release dated October 1, 2024), conveyor (installation of a new conveyor was completed last week), vertical bucket conveyor (for movement of ore to the ball mill feed silo), ball mill, raker/classifier, and gravity table. The raker/classifier separates larger material and nuggets, which are passed to the gravity table, from the finer material which reports to the flotation circuit. Improvements and replacements, by the industrial plumber, at the water tower, of certain sections of piping, and various valves this past week has been successful. Proper volume and flow of water is now occurring to the gravity table, flotation cells, and throughout the plant to the tailings pond.

Metallurgy

Previously announced metallurgy studies of ore, from the Company’s Fran Gold project, to determine final froth flotation and reagent requirements for the extraction of gold, are proceeding at Woods Process Services’ Metallurgy Laboratory. Upon completion of the formulation, extraction by flotation at the Bishop Gold Mill will commence. Kappes, Cassiday & Associates has commenced metallurgical studies on ore from the Mt. Vernon Gold Mine for the purpose of detailed ore characterization, report to tailings and to better understand this unique high-grade ore in anticipation of production. Enviro-tech Analytical Labs has commenced gravity separation testing on composite samples from previously assayed material from Mt. Vernon (see Press Release dated October 4, 2024). The purpose of this work is to set a baseline percentage and concentration ratio for recovery of gold, platinum, and silver by gravity separation at the Bishop Gold Mill. The gravity separated concentrate produced at the Bishop Mill will be used to produce dore bars and platinum buttons utilizing the on-site furnace. The furnace is fully operational. Based on prior work, gravity recovery of gold and platinum from Mt. Vernon is expected to be high and the use of the flotation circuit may not be immediately necessary.

Engineering

NewFields, as lead environmental engineers, have filed a revised and updated closure cost analysis (2024 dollars) and tailings pond liner inspection report with regulators. A determination will be made by regulators as to whether to increase the closure bond. The Company currently has a closure bond in place of $250,000. Woods Process Services, in addition to assisting with mill start-up, is now developing mass balances and detailed ore flow and extraction models along with designing the implementation of grade and recovery monitoring systems. Further analyses to determine areas of potential efficiency, recovery, and cost reduction is underway. In particular, the addition of specialized gravity gold concentration equipment such as Knelson concentrators are being considered.

On behalf of the Board of Directors of

NORTH BAY RESOURCES INC.

Jared Lazerson

CEO

info@northbay-resources.com

northbay-resources.com

X: @NorthBayRes

Facebook: North Bay Resources Inc | Facebook

LinkedIn: North Bay Resources Inc | LinkedIn

This news release may contain certain “Forward-Looking Statements” within the meaning of the United States Private Securities Litigation Reform Act of 1995 and applicable Canadian securities laws.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/c5ec6d80-7698-4fb9-81b7-efbafa86a755